Seed

Technologies Corp., Ltd. started its endeavor in developing a unique additive

manufacturing technology (3D printing) in 2015. Seed put together an elite team

of professionals focused on R&D, design, and development of additive

manufacturing material. This team was paired with state-of-the-art additive

manufacturing equipment to develop patented technologies to serve multiple

industries. Seed currently serves a variety of industries such as aviation, oil

&gas, geological exploration, machinery, automotive engineering, and construction.

Materials for Additive Manufacturing Technology

Wear-resistant material / Titanium alloy / High temperature alloy

Refractory metals / Aluminum alloy / Copper alloy / Tool steels etc

|

Capabilities of Additive Manufacturing

Materials

for printing: wear-resistant materials, titanium alloy, High temperature alloy, refractory metal, aluminum alloy, copper alloy,

tool steel, and other materials

Printing

Equipment: State of the Art printing equipment supported by an experienced and professional

technical team

Printing software: STL model compatible

Advantages of our printing technology: 1) Rapid prototyping;

2) Complex structures; 3) small batch production, fast operation at low cost;

4) material saving; 5) distributed production, does not require centralized

manufacturing workshops

|

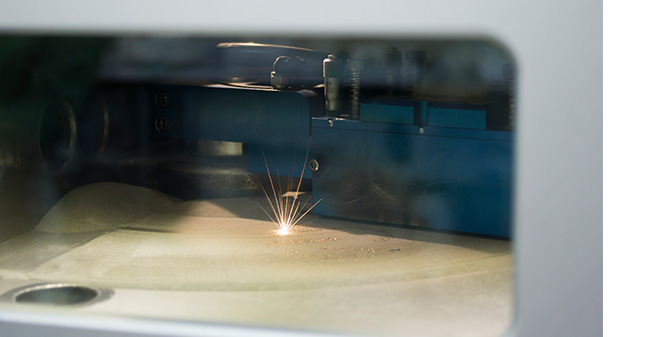

Main 3D Printing Technology

Electron beam melting technology

Laser metal deposition technology

Selective laser melting technology

|

Our Advantages

1、 We can

support new product designs, freely design complex shapes, make molds with

arbitrary complex surface shapes, provide unique manufacturing solutions for

products with complex structures, and help customers achieve their design goals

for new products.

2、 3D Printing can effectively manage the use of materials, reduce

energy consumption, and reduce manufacturing costs to the greatest extent;

small batch manufacturing can realize rapid forming of parts without molds.

3、3D printing technology simplifies the processing

procedures. After the design is completed, it can be directly printed by the

CAD model-driven equipment. This will significantly reduce tedious machining

procedures while greatly improving efficiency to meet customer delivery time

and cost expectations. Overall shortening production times to the market.

4、3D Printing can

meet the personalized needs of customers, and the service system is

comprehensive.

5、The metal parts manufactured by 3D printing have

good inherent quality, fast forming speed, and enhanced wear-resistance. Printable

Metal composite materials are resistant to wear, erosion, and impact, and have

a longer service life. These materials are widely used in aerospace, machinery,

automotive engineering, Geological prospecting and other fields.

Technical Services Provided

1、Process

consulting services: provide guidance on the selection of 3D printing products

and the scope of applicable products; provide the characteristics of materials

according to customers selection; provide services such as the development of

3D printing basic processes and the overall design of the first product.

2、Design optimization service: By taking

advantages of additive manufacturing technology over the limitations of

traditional manufacturing, we provide design optimization services.

3、Business consulting services: Provide consulting

services for the entire additive manufacturing cycle, including material

selection, material performance, applicable parts, applicable industries,

product design and modeling.

4、Repair and remanufacturing

services: repair and remanufacturing of repairable materials such as titanium

alloy, superalloy, stainless steel, and alloy steel to improve production

efficiency.

Quality, Innovation

Seed is committed to the innovation and design

of 3D printing and has established an innovation and research team to further

explore in depth the application of additive manufacturing in various

industries. Focusing on technological innovation services, the uniqueness of additive

manufacturing processes together with the superior properties of the specialized

materials makes the manufactured tools more suitable for the unique environment

in the industry. It is our goal to provide special additive manufacturing tool

parts for the most challenging working conditions and strive to become a strategic

partner to provide our customers with solutions.